Services

METAL CLADDING

Types:

1. Aluminum Composite Panel Cladding (ACP)

Aluminum Composite Panel (ACP) is composed of thermoplastic core of lowdensity polyethylene or non-combustible mineral filled core sandwiched between two skins of 0.5mm thick aluminium. The top side or the external visible face is finished with Lumiflon-based fluorocarbon paint as standard & backside or internal non-visible face is finished with thin polyester COATING OR A SERVICE COATING.

Specifications:

Characteristics:

Area of application:

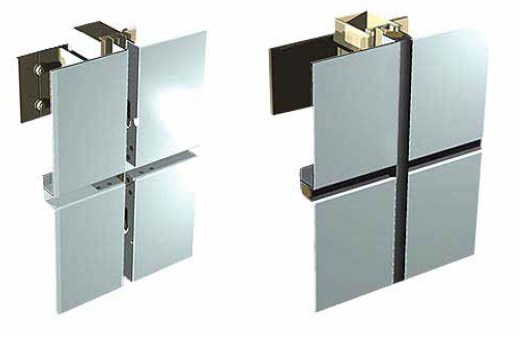

Method of fixation:

Different types of fixation methods based on customer requirements are available like cleat fixation with wet sealant joint, hooking or hanging system with open joint etc.

Area of application:

Method of fixation:

Different types of fixation methods based on customer requirements are available like cleat fixation with wet sealant joint, hooking or hanging system with open joint etc.

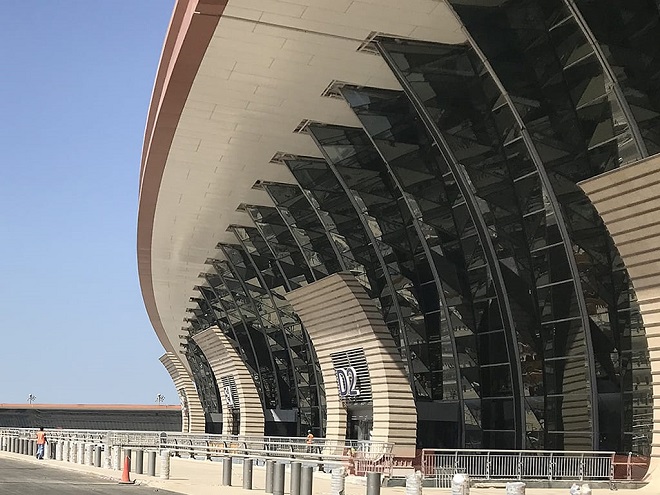

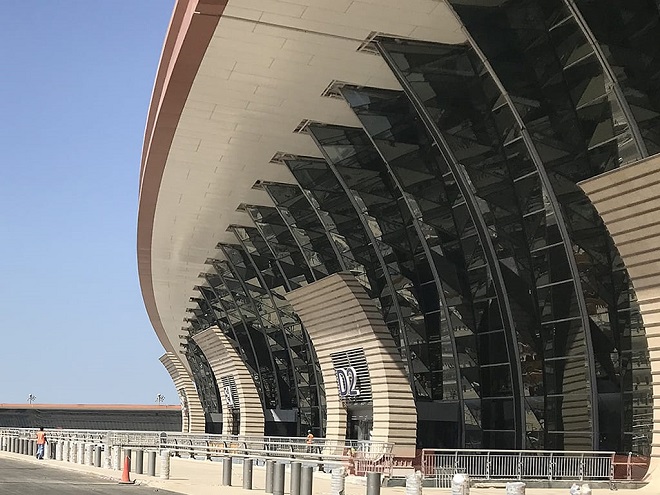

2. Stainless Steel Cladding

Stainless steel cladding is durable and weather resistant .it is used for reason for imbibing a aesthetic effect to the facade where used. It is used in multiple thicknesses as per the requirement of the architect. The applications involve curved or straight, the finish of stainless steel cladding can be mirror or brush finish or matt finish as per the requirement of the client. Generally, SS316 or marine grade is used for external applications & SS304 for internal applications. The application are store fronts, atrium cladding, automatic entrances decoration etc.

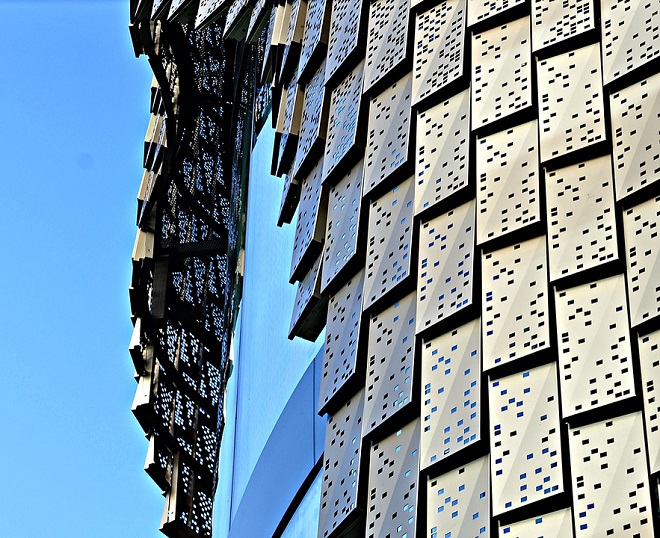

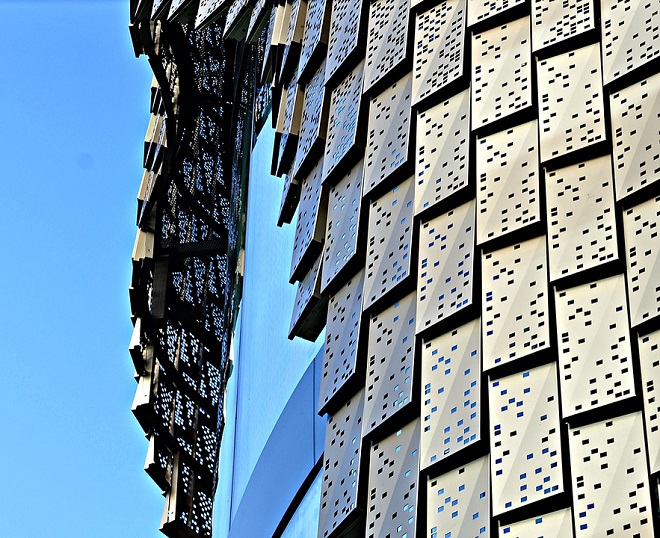

3. Perforated Sheet Cladding

Difference types of metals & finishes are applicable to provide a smart perforated design even for internal or external facade with wide range of designs by using advance technology of metal shaping & cutting machines like (CNC , Water Jet & Laser Machines) . Steel, Stainless Steel & Aluminum Sheets are mostly used to produce the required design or pattern refer to high resistance corrosion & extreme weather conditions.